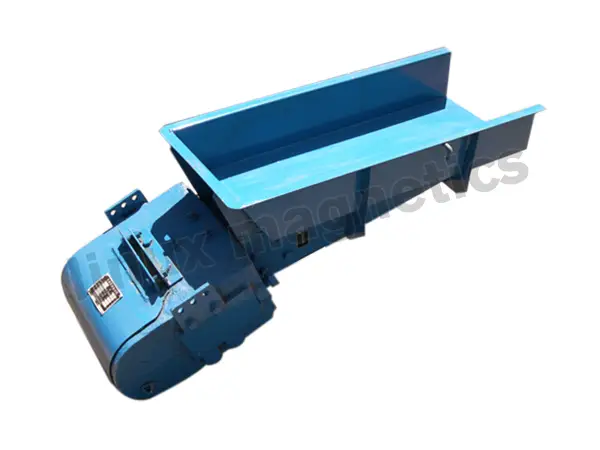

Backed with our rich manufacturing understanding in this field of manufacturing of Electro Magnetic Vibro Feeder, we are keenly affianced in presenting a extensive assortment of the product. These feeders use both vibration and gravity to move material. The offered Electro Magnetic Vibro Feeder is widely used to remove or receive material and transport it homogeneously for more processing. Besides this feeder is used in processing industries for handling all types of materials such as hot, damp, lump, dusty or uncompromising for a variety of functions like flow of material from storage, proportioning, packaging, mixing, weighting, sprinkling, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and bending etc.